Industrial Dust Collection Systems

Long-lasting Systems for Any Project Scope

If you need to capture an elusive or difficult particulate, fit an industrial dust collector into a challenging space or ensure that your system requires minimal maintenance downtime, IVI stands ready. We work with you to design every part of your industrial dust collection system, optimizing to meet environmental and air quality standards.

From 50 to 1 million CFM, across any industry, our team stands ready to design and engineer, fabricate and install a long-lasting turn-key solution for you.

Industrial Dust Collectors Built for Longevity

IVI dust collectors are built to last. Our engineering and design teams specify fabrication with metals and varying alloys selected for your environment, particulates and processes. Then, we fabricate those designs in-house, ensuring we exceed your high standard of quality and longevity.

Enhance Your Facility’s Production Process

A skillfully built industrial dust collection system will:

Improve Air Quality

Reduce workers’ exposure to hazardous particulates

Reduce Airborne Particulates

reduce Fire and Explosion Hazards

Improve productivity Through Ease-Of-maintenance

A System for Any Need

Our first step in engineering and designing an industrial dust collection system is understanding your needs. During an on-site visit, we’ll examine your processes’ configuration to determine ductwork, hoods and dust collector installation. With project scope complete, we collaborate with you to create a plan for your new or upgraded industrial dust collection system.

We offer several types of systems:

Baghouse Dust Collectors

Your baghouse will be designed specifically to your application. We’ll take into account your particulate type, explosion hazards, filtration efficiency needs, and lots more to ensure your baghouse gets the best performance and lifespan.

Mechanical Separation

If you need to remove heavy particulates from the air, we will customize the device to fit your application. Our mechanical separation devices include classifiers, cyclone separators and drop-out boxes.

Cartridge Dust Collectors

When you need to capture fine, dry dust or smoke, your best option may be a cartridge dust collector that features a large filter area relative to its size.

Fume Collectors

If you need to ventilate noxious fumes, you’ll require a specific solution, like a fume collector that includes scrubbers and fume hoods, to rid your facility of these hazardous airborne particulates (HAPs).

Industrial Dust Collection Problems Solved

Unique challenges. Every project has them. They fuel IVI engineers and designers to find solutions that work. A few examples:

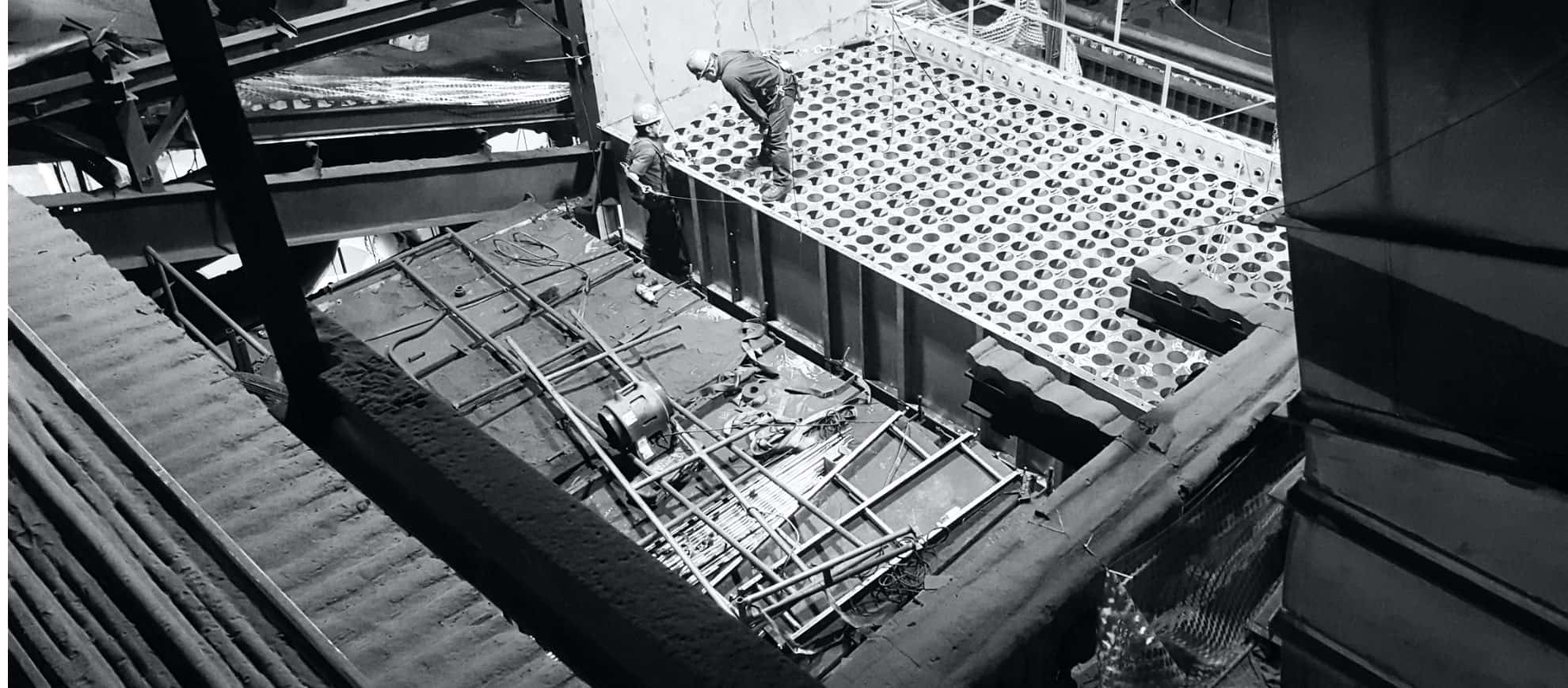

- A foundry customer required a 30,000-cfm dust collector that was to be located in the center of the plant. Dropping it through the roof with a large crane wasn’t feasible, nor was there adequate room to bring large pieces into the facility. To install, we broke it into 5-foot and 10-foot pieces and built it in place.

- A large industrial customer needed a sizable system, but the factory had no room for industrial dust collector installation. The IVI engineering and design team looked overhead, calculated load weights and determined the baghouse could be installed on the roof.

These are just two of the many examples of the problem-solving capabilities IVI engineers bring to address your industrial ventilation needs.

Are you ready to improve air quality, efficiency and maintenance?

Contact us to get started on an industrial dust collection system designed specifically for you.