industrial ventilation Design & engineering

Industrial Ventilation Design: Keeping an Eye on Your Goals

Whether you’re looking for an industrial dust collector or a complete industrial ventilation system, you may have myriad goals—improving your indoor and outdoor air quality, boosting production efficiency, reducing maintenance and lowering costs.

At IVI, we approach industrial ventilation design with the end in mind.

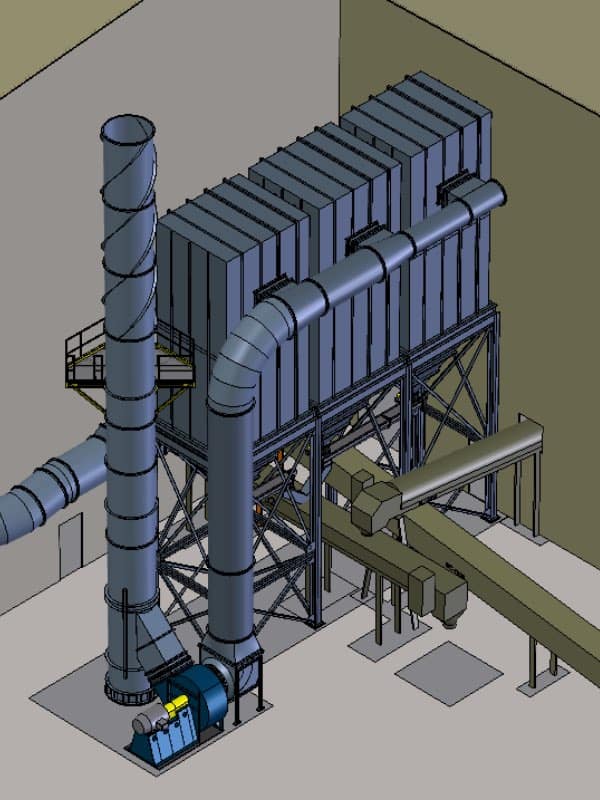

Designing a dust collection system specific to you means efficiently capturing particulates, fitting your space and meeting stringent regulatory requirements. Your goals drive every decision, at every point in the design process.

Understand the Current State. Design the Future State.

You may not see how air and dust flow through your facility and industrial ventilation system, but thanks to technology, IVI’s engineering and design team makes the invisible visible. We use a variety of methods to understand the current state–the first phase in your industrial ventilation design project:

Industrial Air Quality Testing

This survey determines if processes and industrial ventilation systems are working effectively. It’s often our first step in designing a system fit for you.

Air Flow Analysis

To ensure your system works efficiently, we visualize your air flow using our computational fluid dynamics software. Our in-house R&D test lab also helps us visualize exactly how air flows through a room.

Ventilation Testing and Balancing

Considered an art and a science, ventilation testing and balancing done after your system is installed ensures it is operating at peak efficiency to save you energy costs and extend your dust collector’s life.

Industrial Ventilation Maintenance

While industrial air quality testing and an air flow analysis are often the first phase in industrial ventilation design, we also conduct these analyses independent of a new project. The results may indicate needed upgrades or the need for regular industrial ventilation maintenance to enhance your system’s performance.

Proven Process. Proven Products.

Whether we design a single dust collector or an entire system, we approach each project with the same proven strategy.

Here’s how we put our design and engineering process to work for you:

Seek to Understand the Problem: Together, we discuss your goals of the project.

Explore the Possibilities: Then we develop ways we can help meet your goals.

Select the Best Approach: We determine the right baghouse or system solution for you.

Design a Solution: Our designers and engineers create the solution to spec.

Test & Evaluate: Before fabrication, we ensure the design meets your goals.

Refine the Solution: If necessary, we adapt the design.

Build: Then, the project moves on to our in-house fabrication team.

Install: You can depend on our safe, efficient installation team to ensure your baghouse or ventilation system meets your goals.

You can rely on transparency throughout the process—we communicate and collaborate during each step of your industrial ventilation project.

Request an Analysis

Have you been looking for a single-source industrial ventilation design partner to get your facility running at peak performance? Contact us to get started.

"*" indicates required fields